Insect farming equipment issues for small agribusinesses typically fall into several key areas Breaking Down the Problem Insect Farming Equipment Challenges:

- Equipment Selection: Choosing the wrong equipment for the insect species or scale of operation.

- Setup and Installation: Improper setup leading to inefficiencies or equipment failure.

- Maintenance and Operation: Lack of proper maintenance or operational knowledge causing downtime or reduced productivity.

- Environmental Control: Inability to maintain optimal conditions (temperature, humidity, ventilation) for insect growth.

- Scalability and Cost: High initial costs or equipment not suited for scaling operations.

Common Causes

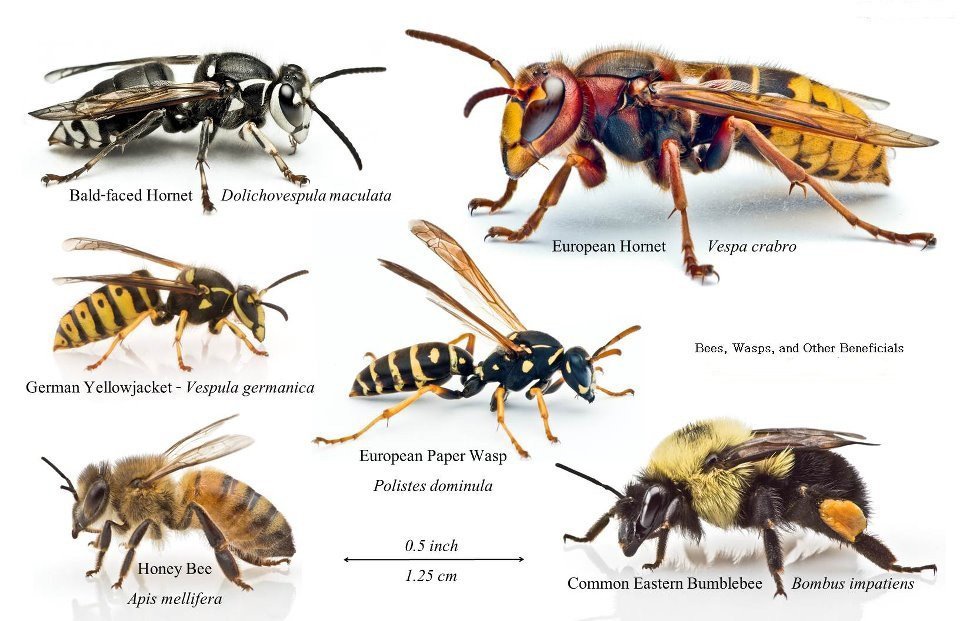

- Lack of Knowledge: Many small agribusiness owners are new to insect farming and may not understand the specific equipment needs for different species (e.g., Black Soldier Fly, crickets, or mealworms).

- Budget Constraints: Limited funds lead to purchasing low-quality or inadequate equipment.

- Poor Planning: Failing to design systems for scalability or environmental control.

- Neglected Maintenance: Inconsistent maintenance schedules or lack of training on equipment use.

- Supplier Issues: Sourcing equipment from unreliable suppliers, leading to disease risks or poor performance.

Consequences of Not Addressing Equipment Issues

- Reduced Productivity: Suboptimal equipment can lower insect yields, impacting revenue.

- High Costs: Frequent repairs or replacements due to poor equipment choices increase expenses.

- Health Risks: Poorly maintained equipment can lead to disease outbreaks in insect colonies.

- Environmental Impact: Inefficient systems may consume more energy or fail to process waste effectively.

- Lost Opportunities: Inability to scale or meet market demand can result in lost customers or contracts.

Actionable Step-by-Step Solutions

To address these challenges, small agribusinesses can follow these steps to select, set up, and maintain effective insect farming equipment.

Step 1: Assess Needs and Select Appropriate Equipment

- Action: Identify the insect species (e.g., Black Soldier Fly, mealworms, crickets) and the intended output (e.g., animal feed, human consumption, fertilizer). Match equipment to the species’ biological needs and your production goals.

- Tools/Resources:

- Research guides from organizations like the FAO (Food and Agriculture Organization) or Flybox (www.flybox.bio) for species-specific requirements.

- Consult with certified suppliers for starter colonies and equipment recommendations.

- Example Equipment:

- Breeding Cages: Mesh cages for air circulation and egg-laying substrates (e.g., corrugated cardboard for BSF).

- Feeding Bins: Containers for organic waste or feed, sized for your operation (small bins for 10–50 kg waste/day).

- Climate Control Systems: Heaters, humidifiers, and ventilation fans to maintain conditions (e.g., 28–30°C, 60–70% humidity for BSF).

- Tips:

- Start small with modular equipment to test systems before scaling.

- Budget for initial investments of £8,000–£80,000, depending on scale, with expected ROI of 30–50% within two years for BSF farming.

Step 2: Plan and Set Up Equipment Properly

![]()

- Action: Design a layout that optimizes space, workflow, and environmental conditions. Ensure proper installation of equipment to avoid operational issues.

- Tools/Resources:

- Use free farm planning tools like AgPlan (www.agplan.umn.edu) to design layouts and identify resource needs.

- Hire a local technician or consult supplier manuals for installation guidance.

- Steps:

- Allocate space (e.g., a few square meters for small operations or modular containers for larger setups).

- Install breeding cages and feeding bins with secure fittings to prevent insect escapes.

- Set up climate control systems with sensors to monitor temperature and humidity.

- Test equipment functionality before introducing insect colonies.

- Example: A small BSF farm in Kenya used modular containers with automated climate control to process 100 kg of organic waste daily, reducing setup errors by following supplier guidelines.

Step 3: Implement a Maintenance and Operation Schedule

- Action: Create a regular maintenance and monitoring schedule to ensure equipment longevity and colony health.

- Tools/Resources:

- Maintenance checklists from equipment suppliers or online resources like SARE (www.sare.org).[](https://www.sare.org/resources/manage-insects-on-your-farm/)

- Digital farm management systems like CropX for tracking equipment performance and environmental data.

- Steps:

- Clean and disinfect equipment weekly to prevent disease (e.g., remove frass and residues from bins).

- Check climate control systems daily for consistent temperature and humidity.

- Rotate breeding stock every 6–8 weeks to prevent inbreeding and maintain colony health.

- Train staff on equipment operation using supplier manuals or online training from platforms like UC IPM (ipm.ucanr.edu).

- Example: A mealworm farm in the Netherlands reduced downtime by 20% by implementing a weekly cleaning schedule and using automated sensors to alert staff to humidity fluctuations.

Step 4: Optimize Environmental Control

- Action: Maintain optimal conditions for insect growth using climate control systems and monitoring tools.

- Tools/Resources:

- Affordable sensors for temperature, humidity, and ventilation (e.g., CropX soil and weather sensors).

- DIY solutions like solar-powered ventilation for small setups.

- Steps:

- Install sensors to monitor conditions in real-time (e.g., 28–30°C for BSF larvae).

- Adjust ventilation to prevent mold and ensure air circulation.

- Use backup power sources (e.g., solar panels) to maintain climate control during outages.

- Example: A cricket farm in Thailand improved larval survival rates by 15% by installing low-cost humidity sensors and adjusting ventilation based on real-time data.

Step 5: Plan for Scalability and Cost Management

- Action: Choose modular equipment that allows for gradual scaling and implement cost-saving strategies.

- Tools/Resources:

- Financial planning tools from the USDA (www.usda.gov) or local agricultural extension services.

- Grants or loans for sustainable agriculture from organizations like FAO or local governments.

- Steps:

- Start with equipment that can be expanded (e.g., stackable breeding cages).

- Track costs using software like CropX to optimize resource use.

- Apply for grants to offset initial costs, such as those for waste management systems.

- Example: A BSF farm in South Africa scaled from 50 kg to 500 kg of waste processing per day by investing in modular bins, funded partly by a local sustainability grant.

Case Study: Black Soldier Fly Farm in Mwea West, Kenya

Background: A small agribusiness in Mwea West, Kenya, aimed to process organic waste and produce BSF larvae for animal feed. They faced challenges with equipment selection and environmental control.

Solution:

- Equipment Selection: They chose modular breeding cages and feeding bins from a certified supplier to match their 100 kg/day waste processing goal.

- Setup: They used AgPlan to design a compact layout in a 10-square-meter shed, installing low-cost climate control systems.

- Maintenance: A weekly cleaning schedule and staff training reduced disease outbreaks.

- Environmental Control: Affordable humidity sensors ensured optimal conditions (28°C, 65% humidity).

- Scalability: They applied for a local grant to purchase additional bins, doubling capacity within a year.

Outcome: The farm processed 100–200 kg of waste daily, generating £10,000 in annual revenue from larvae and frass sales, with a 40% ROI in 18 months.

Prevention Tips for Future Success

- Research Thoroughly: Study the biological needs of your chosen insect species using resources like FAO or UC IPM to select compatible equipment.

- Choose Reliable Suppliers: Source equipment and starter colonies from certified suppliers to avoid disease risks.

- Invest in Training: Train staff on equipment use and insect biology through online courses or local extension services.

- Monitor Regularly: Use digital tools like CropX to track environmental conditions and equipment performance.

- Plan for Scalability: Opt for modular systems that allow gradual expansion without major reinvestment.

- Maintain Hygiene: Regular cleaning and sanitation prevent disease and prolong equipment life.

- Stay Updated: Follow industry updates from sources like Flybox or SARE to adopt new technologies and practices.

Next Steps and Call to Action

- Assess Your Needs: Identify your insect species and production goals within the next week.

- Research Equipment: Contact certified suppliers and review resources like Flybox (www.flybox.bio) or FAO (www.fao.org) for equipment recommendations.

- Create a Plan: Use AgPlan to draft a farm layout and equipment list within two weeks.

- Start Small: Purchase and install initial equipment, testing systems with a small colony within one month.

- Monitor and Adjust: Implement a maintenance schedule and use sensors to track performance, reviewing results monthly.

- Seek Support: Contact local agricultural extension services or apply for grants to support your setup.

Take Action Now: Insect farming is a sustainable, profitable opportunity for small agribusinesses, but success depends on choosing and maintaining the right equipment. Start today by researching your options and setting up a small-scale system to test your approach. Visit www.flybox.bio or www.fao.org for guides and supplier contacts, and take the first step toward a thriving insect farming operation